Reliable Steel Distributors is one of the leading alloy 926 pipes and tubes manufacturers and suppliers. Our adherence to quality and excellence has made us one of the giant names in manufacturing high-performance material. Alloy 926 is a nickel-chromium-molybdenum stainless steel especially designed to offer resistance to harsh environments and exceptional resistance against pitting and crevice corrosion. With a number of years in industrial experience, we will be able to provide item manufacturing to a wide variety of applications in the fields of chemical processing, oil and gas marine, or other industries.

The chemical composition of Alloy 926 is unique and particularly suited to applications involving critical resistance to corrosion caused by chlorides. With its high nickel content, this alloy retains strength and toughness even at elevated temperatures.

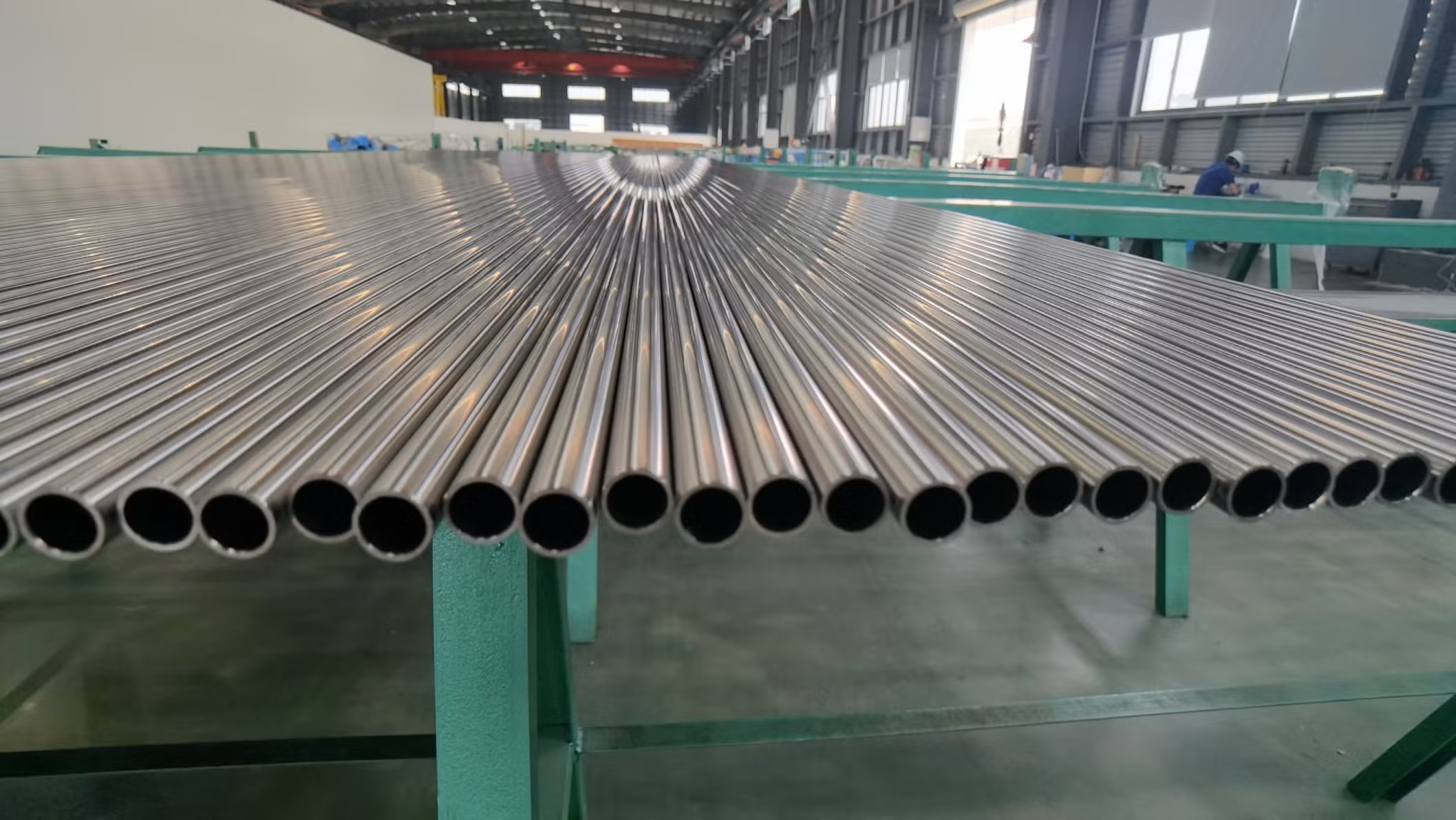

At Reliable Steel Distributors, alloy steel 926 pipes and tubes are manufactured into reliable products for our customers by observing stringent industrial standards. Our products are rigorously tested to assure quality and subsequently deliver outstanding service performance in the most extreme conditions. Reliable Steel Distributors are trustworthy stockists and exporters of Alloy 926 pipes and tubes. We offer a full suite of inventory to meet the requirements of our customers with regard to size and dimensions. We store a comprehensive range of sizes and dimensions, thereby enabling us to fulfill standard as well as customer orders in an efficient manner.

Alloy 926 Pipes & Tubes, Alloy 926 Pipes & Tubes Manufacturers, Alloy 926 Pipes & Tubes Suppliers, Alloy 926 Pipes & Tubes Stockists, Alloy 926 Pipes & Tubes Exporters

Accordingly, we are proud of our expert team, which is invested in excellent customer service by walking a client through the selection process to ensure just the right products for their specific needs.

Alloy 926 Pipes & Tubes Manufacturers in India, Alloy 926 Pipes & Tubes Suppliers in India, Alloy 926 Pipes & Tubes Stockists in India, Alloy 926 Pipes & Tubes Exporters in India

Along with our big inventory, Reliable Steel Distributors also work for sustainability and the responsible sourcing of materials. Besides taking operations concerning ecological safety, we liaise with manufacturing processes of suppliers that do not compromise on ethics. It would help to take care of our planet and keep the integrity and reputation of the products among the customers in the marketplace.

Choosing a trusted Alloy 926 steel distributor is a journey of trust in quality, customer satisfaction, and innovation. Continuous investment in technology and research enables the group to remain at the top in this industry and to offer our customers the latest available materials. Be it manufacturing, supplying, or even contracting, one can always bank on us for Alloy 926 products that are of the highest quality and to one's exact specification.

Alloy 926 Pipes & Tubes Manufacturers in Mumbai, Alloy 926 Pipes & Tubes Suppliers in Mumbai, Alloy 926 Pipes & Tubes Stockists in Mumbai, Alloy 926 Pipes & Tubes Exporters in Mumbai

| Property |

Specification |

| Material |

Alloy 926 |

| Standard |

ASTM A312, ASTM A358, ASTM A213, ASTM A269 |

| Composition |

Nickel (Ni) 24-26%, Chromium (Cr) 20-22%, Iron (Fe) Balance, Molybdenum (Mo) 6-7%, Manganese (Mn) 1.5%, Silicon (Si) 0.75%, Nitrogen (N) 0.1%, Carbon (C) 0.02% max |

| Size Range |

1/8" to 30" (Outside Diameter), SCH 5S to SCH 160 |

| Wall Thickness |

Schedule 5S, Schedule 10S, Schedule 40, Schedule 80, Schedule 160 |

| Length |

Up to 12 meters (custom lengths available) |

| Temperature Resistance |

Up to 1100°F (600°C) |

| Corrosion Resistance |

Excellent resistance to chloride stress corrosion cracking, pitting, and crevice corrosion |

| Application |

Chemical processing, power generation, oil and gas, marine, paper and pulp industries |

| Form |

Seamless and Welded Pipes & Tubes |

| Finish |

Pickled, Polished, Annealed |

| Testing |

Hydrostatic Test, Mechanical Test, Chemical Test, PMI Test |

| Packaging |

Wooden Boxes, Bundles, Shrink Wrapped |

| Standard |

Grade |

Equivalent Grade |

| AISI |

926 |

UNS N08926 |

| ASTM |

Alloy 926 |

ASTM A312, ASTM A213, ASTM A269 |

| ASME |

Alloy 926 |

ASME SA312, SA213, SA269 |

| DIN |

1.4529 |

Alloy 926 |

| JIS |

SNCC 20 |

Alloy 926 |

| BS |

Alloy 926 |

BS 3601, BS 3602 |

| Element |

Composition (%) |

| Nickel (Ni) |

24.0 - 26.0 |

| Chromium (Cr) |

20.0 - 22.0 |

| Molybdenum (Mo) |

6.0 - 7.0 |

| Iron (Fe) |

balance |

| Copper (Cu) |

0.5 max |

| Manganese (Mn) |

1.0 max |

| Silicon (Si) |

1.0 max |

| Carbon (C) |

0.03 max |

| Phosphorus (P) |

0.02 max |

| Sulfur (S) |

0.01 max |

| Titanium (Ti) |

0.3 - 0.8 |

| Aluminum (Al) |

0.05 max |

| Vanadium (V) |

0.1 max |

| Niobium (Nb) |

0.05 max |

| Property |

Value |

| Tensile Strength |

690 MPa (min) |

| Yield Strength |

275 MPa (min) |

| Elongation |

40% (min) in 50mm |

| Hardness (Rockwell B) |

90 HRB (max) |

| Modulus of Elasticity |

200 GPa |

| Poisson's Ratio |

0.3 |

| Density |

8.0 g/cm³ |

| Thermal Conductivity |

15.8 W/m·K |

| Coefficient of Thermal Expansion |

13.3 µm/m·K (20–100°C) |

| Melting Point |

1390–1430°C |

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Philippines

Philippines Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Kazakhstan

Kazakhstan Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela